BurButler -The concept of the design.

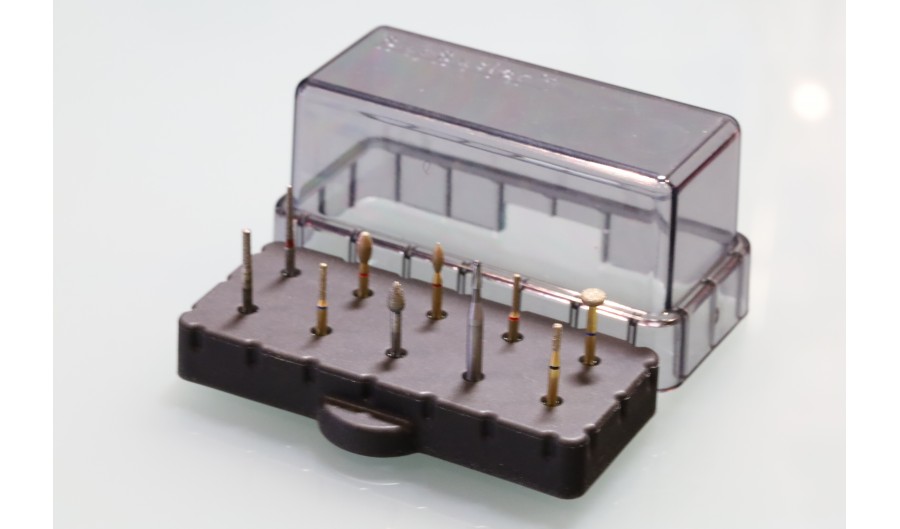

The BurButler Design

This little product went to market. The process of design to production, by Hazel Hendy MBA & Dr Paul Moore BDS

This has been a team effort. Two heads are better than one and working together as a team has meant at all times each of us could bounce ideas of each other and each lend our own range of skill sets and knowledge to reach where we are today in 20 countries including USA, Canada, Australia, Korea, UK, Spain, Norway, Portugal, Netherlands, Saudi….

Being a dentist for nearly 40 years has been a great big long learning curve with some sharp corners, and constant development of ideas, design and engineering. That’s the job. I think it is a natural part of a dentist’s training and nature to want to consider ways of improving what we do and how we do it, to develop a theoretical idea into a practical solution.

But it takes more than the idea to design a product. It needs a driving force to refine your ideas, to market and promote your concept, to engage with the industry, the people, the dentists and the companies. Ten years ago we started a new company to develop ideas we had had to improve the efficiency of the practice.

We often get asked..”What is the process for a new product development” ....Need is the spark of Innovation. What is the problem to solve?

The BurButler

The first stage in any product development is to write down your ideal ambitions and then design your features.

So we brainstormed the ideal bur block concept and features and contrasted them to the classical solutions out there.

1. Base and Lid must both be an autoclavable material.

- Many of the still used burstands simply cannot be autoclaved either because they have plastic bases or lids.

- Nowadays with increased awareness of Covid - compliance this is even more unacceptable.

2. No moving or parts that deteriorate requiring replacement.

- Bungs and hinges create “dead” spots where debris and bacteria might accumulate and as surfaces deteriorate they become rougher.

- To replacement bung sets is costly and at what stage of deterioration should they be replaced.

3. Every hole should grip very bur shank, fiction, latch or lab snugly but each should be easily removable.

- With solid burblocks, the dentist has to work with a set layout and the burs fall out if the block is tipped.

4. The cover should autoclavable but be clear and closed to protect the burs from the aerosol effect in a dental surgery.

- This is essential to see but protect the contents. They should also be removable one handed.

- Bung type bur blocks all have open metal lids or partial covers.

- The bungs offer another interface to clean and they have to be replaced as they deteriorate.

- The open lids cannot protect against aerosol effect.

- Our cover has a unique interface with the BurButler base that allows steam to breathe though the interface , but the groove in the base of the BurButler give a gentle but positive tension to the grip just right. The cover can be removed and replaced one handed during a procedure.

- Many of the plastic bur stands have no cover. Some still in use cannot be autoclaved.

5. Burs should not be magnetised.

- Magnetic bur stands transfer the magnetism to the shanks. This causes the burs to stick to other instruments.

6. Bacteriological verification of the efficacy of the product is essential.

- Independent bacteriological testing by an authoritative body is a non negotiable requirement.

7. Use with “Single use burs”?

- Even for single use burs the process of chair side presentation should dictate that the gloved dentist has all the dental burs they require presented so that they do not have to “fish” for burs while wearing gloves, or open packaging without sterile gloves on.

- The packaging of single use burs is not sterile. Open your single use burs and set them up for your procedures for the day. All the burs you require for that procedure are then available without having to sort through and cross contaminate the packaging while looking for the bur he needs.

8. Each dentist should know which burs in the practice belong to their own surgery.

- This one was easy - colour coding the Bases will allow each dentist or surgery to have their own colour.

9. Burs should be autoclavable when in situ during the sterilisation process.

- Dental burs should not touch each other in the autoclave. Not having to remove the burs will reduce handling, reduce hazards to the team, saving time, prevent loose burs and increase organisation.

10. Spacing between the dental burs should be such that dentists can access them single handed without tweezers and lift and replace them with ease.

- So we set to on the design process. Fist designing the hole shape to be a “parabolic” funnel so each bur will grip at the diameter of the end of the inserted bur.

- The holes were designed through and through to allow drainage and fluting and location “buds” to centralise the burs when they are placed would allow irrigation and steam penetration.

- Solid silicon bases would give integrity of the bases and allow flexibility to grip the burs. Silicon also has natural antimicrobial properties and is suitable for high temperatures required for autoclaving.

- We researched a translucent lid polymer material and designing the junction to the base to allow steam penetration with raised vertical ridges on the skirt of the closed lid. The base was modified to “collapse” when engaged by the lid to create a grip between base and lid.

BurButler is one of those products that makes life easy. It is a systematic approach to solve a problem of safe and efficient dental bur management from chair side through sterilisation and back to chair side.

38 Comment(s)

natural bodybuilding vs steroids pictures

best place to order steroids online

are steroids made from cholesterol

grand parker casino

turning stone casino

mahjong more time

roulette tabs

https://music.growverse.net/lou66440981529\r\n\r\n\r\nhttps://img.lodis.se/jacobrandall14/4474blackcoin.co/wiki/Fair-Go-Casino-AU-Review-Bonuses%2C-Promotions%2C-Games\r\n\r\n\r\nhttps://www.myminglemate.com/@adamhuitt63436\r\n\r\n\r\nhttps://palkwall.com/read-blog/82079_star-is-staring-down-administration-if-liquidity-concerns-aren-039-t-resolved.html\r\n\r\n\r\nhttps://musixx.smart-und-nett.de/norineworley43\r\n\r\n\r\nhttps://vila.go.ro/abdulclaypool5\r\n\r\n\r\nhttps://worship.com.ng/jonellesturgis\r\n\r\n\r\nhttps://heylloow.com/@carmonamerson8\r\n\r\n\r\nhttps://grafana.jasonstolle.com/adanreddy05054/adan2009/wiki/New-Mexico%27s-Best-Bet\r\n\r\n\r\nhttps://yooverse.com/@adelineloggins\r\n\r\n\r\nhttps://gitea.nongnghiepso.com/alfredozinn806\r\n\r\n\r\nhttps://scrape.weidautzel.de/carmellaneuman\r\n\r\n\r\nhttps://hgngit.ipdz.me/gabriellavende\r\n\r\n\r\nhttps://git.gaminganimal.org/jerrode9039622\r\n\r\n\r\nhttps://git.gaminganimal.org/georgiakeysor\r\n\r\n\r\nhttps://www.arabianmatrimony.com/@kit30c6719368\r\n\r\n\r\nhttps://www.ilife24.com/adeleemma7343/adele1998/wiki/RocketPlay+Casino%253A+Unleash+Your+Gaming+Thrills+with+Exciting+Bonuses+and+Seamless+Experience\r\n\r\n\r\nhttps://mystdate.com/@treysilcock856\r\n\r\n\r\nhttps://git.thweb.net/bertha01d07015\r\n\r\n\r\nhttps://liebiwelle.com/@alanavela02052\r\n\r\n\r\nhttps://purednacupid.com/@altonkrichauff

https://www.bondhuplus.com/read-blog/266988_official-website.html\r\n\r\n\r\nhttps://git.zhukovsky.me/esperanzaeox8\r\n\r\n\r\nhttps://wildtribes.net/read-blog/26087_casino-mate-australia-trusted-online-casino-for-real-money-play.html\r\n\r\n\r\nhttps://www.nxgit.xyz/randellvail566\r\n\r\n\r\nhttps://git.ides.club/leonory7981516\r\n\r\n\r\nhttps://www.ilife24.com/wallaceharness/2935402/wiki/Crown+Coins+Casino+Review+2025%253A+Get+100k+CC+++2+SC+Free\r\n\r\n\r\nhttps://git.temporaryname.org/alberthameza47\r\n\r\n\r\nhttps://gitea.mpc-web.jp/tammiburgett91\r\n\r\n\r\nhttps://mockway.cpolar.top/chljoyce51253\r\n\r\n\r\nhttps://ophiuchus.wiki/rosalinestoltz\r\n\r\n\r\nhttps://www.bondhuplus.com/read-blog/267031_fair-go-casino-login-sign-in-to-your-player-account.html\r\n\r\n\r\nhttps://git.fasteur.cn/gracielawerthe\r\n\r\n\r\nhttps://git.outsidecontext.solutions/maureenbernste/maureen1997/wiki/Sign-In-to-Your-Account-Safely\r\n\r\n\r\nhttps://git.lucas-michel.fr/brentfaith5487\r\n\r\n\r\nhttps://maru.bnkode.com/@keenanneil6172\r\n\r\n\r\nhttps://git.daoyoucloud.com/audreashores1/3097blackcoin.co/wiki/Login%2C-Welcome-Bonus-Up-To-%241000\r\n\r\n\r\nhttps://www.singuratate.ro/@jodyfarnsworth\r\n\r\n\r\nhttps://zekond.com/read-blog/288499_best-online-casino-australia-au-real-money-casinos-2025.html\r\n\r\n\r\nhttps://koseongnam.com/aleisha15n795\r\n\r\n\r\nhttps://git.moguyn.cn/annetthypes53\r\n\r\n\r\nhttps://rjlove.org/@charlinechrist

https://wiki.idealirc.org/pamshumway9320\r\n\r\n\r\nhttps://poptop.online/read-blog/19764_australia-039-s-trusted-online-casino.html\r\n\r\n\r\nhttps://hgngit.ipdz.me/allenkunkle691\r\n\r\n\r\nhttps://lius.familyds.org:3000/aprilwhisman12/blackcoin.co6946/wiki/Premium-Online-Gaming-Experience-in-Australia\r\n\r\n\r\nhttps://sound.floofbite.com/glindagovan569\r\n\r\n\r\nhttps://git.ellinger.eu/ahpklara726535/5831blackcoin/wiki/Skycrown-Casino-Reviews-Read-Customer-Service-Reviews-of-skycrown-com\r\n\r\n\r\nhttps://gitea.micro-stack.org/bobby051276659\r\n\r\n\r\nhttps://gitea.theaken.com/dorothycopley\r\n\r\n\r\nhttps://nychat.in/read-blog/2376_instant-pokies-amp-fast-payouts.html\r\n\r\n\r\nhttps://onetouch-git.thxpace.com/lilasatterfiel\r\n\r\n\r\nhttps://supardating.com/@lorrimacansh5\r\n\r\n\r\nhttps://zm.aosenhw.com/@monicacrist58\r\n\r\n\r\nhttps://gitea.micro-stack.org/epifaniavangun\r\n\r\n\r\nhttps://git2.huai-yun.com/amberv72486427/9844922/wiki/Rocket-Play-Casino-Australia-Login-And-Bonuses\r\n\r\n\r\nhttps://supardating.com/@kellykeys56052\r\n\r\n\r\nhttps://k0ki-dev.com/susie42r891513\r\n\r\n\r\nhttps://zoucast.com/jamemoulton882\r\n\r\n\r\nhttps://gogs.qindingtech.com/taniagardiner3\r\n\r\n\r\nhttps://k8cutv01.it.ntnu.no/aguedaanivitti/blackcoin3368/wiki/Campo%252C+CA+Daily+Weather\r\n\r\n\r\nhttps://spinvai.com/eddyminor89184\r\n\r\n\r\nhttps://naijasingles.net/@alejandraputil

https://hgngit.ipdz.me/eleanorsena040/blackcoin.co1996/wiki/Star-Entertainment:-Casino-operator%27s-shares-plummet-after-trading-halt%2C-company-on-brink-of-collapse-with-%27material-uncertainty%27-about-future\r\n\r\n\r\nhttps://git.fasteur.cn/gracielawerthe\r\n\r\n\r\nhttps://git.hanckh.top/aliciakinchelo\r\n\r\n\r\nhttps://isabelzarate.com/graiggardin977\r\n\r\n\r\nhttps://gitlab.grupolambda.info.bo/marceloschrode\r\n\r\n\r\nhttps://git.anacsoft.com/donnellbirchel\r\n\r\n\r\nhttps://wiki.idealirc.org/alvaro66y73089\r\n\r\n\r\nhttps://img.lodis.se/jacobrandall14/4474blackcoin.co/wiki/Fair-Go-Casino-AU-Review-Bonuses%2C-Promotions%2C-Games\r\n\r\n\r\nhttps://shamrick.us/noella18d85248\r\n\r\n\r\nhttps://gitea.jobiglo.com/braydenmcinnis\r\n\r\n\r\nhttps://nuhweh.com/charmainmbj445\r\n\r\n\r\nhttps://git.hundseth.com/arykaren08575\r\n\r\n\r\nhttps://git.fur93.cn:8002/porterholtz66\r\n\r\n\r\nhttps://gitea.kdlsvps.top/jefferyspradli\r\n\r\n\r\nhttps://yooverse.com/@adelineloggins\r\n\r\n\r\nhttps://gogs.qindingtech.com/daciahealy8183\r\n\r\n\r\nhttps://nvuplayer.com/@marta53a49710?page=about\r\n\r\n\r\nhttps://gitea.blubeacon.com/thomassifuente\r\n\r\n\r\nhttps://tippy-t.com/meredith35u669\r\n\r\n\r\nhttps://gitea.nongnghiepso.com/christenawesol/blackcoin.co2006/wiki/Quick-Registration-Guide\r\n\r\n\r\nhttps://seychelleslove.com/@antonyfredrick

https://nrisoulmate.com/@adolphstrzelec\r\n\r\n\r\nhttps://gitea.coderpath.com/ewanbacon7207\r\n\r\n\r\nhttps://git.gaminganimal.org/georgiakeysor\r\n\r\n\r\nhttps://k8cutv01.it.ntnu.no/shaniceglew145\r\n\r\n\r\nhttps://www.lab.justusdeitert.de/gabrielegreenw/2512705/-/issues/1\r\n\r\n\r\nhttps://gogs.playpoolstudios.com/florenemcfadde\r\n\r\n\r\nhttps://git.ellinger.eu/chasrayner402/chas2006/wiki/Discover-Top-Games-and-Bonuses-in-Australia\r\n\r\n\r\nhttps://www.nxgit.xyz/zbzwarren10899\r\n\r\n\r\nhttps://seychelleslove.com/@michelewurst23\r\n\r\n\r\nhttps://schokigeschmack.de/antoniajudkins\r\n\r\n\r\nhttps://git.mikspec.pl/alejandrabardo\r\n\r\n\r\nhttps://seychelleslove.com/@bobbyetheodore\r\n\r\n\r\nhttps://twoheartsagency.com/@garlandmaness3\r\n\r\n\r\nhttps://worship.com.ng/mayralipinski\r\n\r\n\r\nhttps://git.malls.iformall.com/altamcdavid07/blackcoin4943/wiki/King-Billy-Bonus-Codes-2025-No-Deposit-Bonus\r\n\r\n\r\nhttps://hub.hdc-smart.com/tamara11v6749/blackcoin2016/wiki/007%253A+%25D0%259A%25D0%25B0%25D0%25B7%25D0%25B8%25D0%25BD%25D0%25BE+%25D0%25A0%25D0%25BE%25D1%258F%25D0%25BB%25D1%258C+2006+Plot\r\n\r\n\r\nhttps://supardating.com/@ronaldkillinge\r\n\r\n\r\nhttps://syq.im:2025/lakeisha07s056/blackcoin7728/wiki/25-Casino-Psychology-Tricks\r\n\r\n\r\nhttps://worship.com.ng/kenbrotherton5\r\n\r\n\r\nhttps://music.drepic.com/dolliestarling\r\n\r\n\r\nhttps://nuhweh.com/rodspellman49

https://gitea.ysme.top/shennaault0568/shenna1988/wiki/Spoil-a-loved-one-with-Crown-Gifts\r\n\r\n\r\nhttps://gitea.ysme.top/jillian12s6698/blackcoin.co5415/wiki/Sky-Crown-Online-Casino-Slots%2C-Tables-%26-Live-Dealers\r\n\r\n\r\nhttps://www.nxgit.xyz/edithpilgrim6\r\n\r\n\r\nhttps://git.hexaquo.at/fidelphilp162\r\n\r\n\r\nhttps://git.barsisr.fr/berryhcr10022\r\n\r\n\r\nhttps://luvwing.com/@lenardredmond2\r\n\r\n\r\nhttps://nas.zearon.com:2001/alexhewlett063\r\n\r\n\r\nhttps://www.appleradish.org/katharinafanni/katharina2023/wiki/hamber_master_heading%23-Park-Rapids-Lakes-Area-Chamber\r\n\r\n\r\nhttps://lesla.com/@kuwruthie69523\r\n\r\n\r\nhttps://palchat.top/read-blog/9395_king-billy-casino-review-is-legit-safe-in-2025.html\r\n\r\n\r\nhttps://git.outsidecontext.solutions/aletheaold860\r\n\r\n\r\nhttps://gitstud.cunbm.utcluj.ro/ismaelblakey56/ismael1982/-/issues/1\r\n\r\n\r\nhttps://web.panda.id/read-blog/7967_star-entertainment-close-to-collapse-with-casino-group-set-to-run-out-of-cash-be.html\r\n\r\n\r\nhttps://matchmingle.fun/@bonnysnowden86\r\n\r\n\r\nhttps://parkka.heli.asia/read-blog/21086_rocketplay-casino-australia.html\r\n\r\n\r\nhttps://palchat.top/read-blog/9395_king-billy-casino-review-is-legit-safe-in-2025.html\r\n\r\n\r\nhttps://maintain.basejy.com/kaitlyngurule3/blackcoin.co1984/wiki/Richard-Casino-Review-Are-They-Legit-in-2025-%3F\r\n\r\n\r\nhttps://worship.com.ng/violettecortes\r\n\r\n\r\nhttps://git.fur93.cn:8002/ashleighcranfo\r\n\r\n\r\nhttps://git.fur93.cn:8002/ashleighcranfo\r\n\r\n\r\nhttps://gogs.ra-solutions.de/kazukoe5387977

https://romancefrica.com/@agnesborn38309\r\n\r\n\r\nhttps://git.tea-assets.com/inezlyke575545\r\n\r\n\r\nhttps://music.vp3.me/eldonhernandez\r\n\r\n\r\nhttps://music.vp3.me/carridelano008\r\n\r\n\r\nhttps://git.clarue.net/velva43449361\r\n\r\n\r\nhttps://www.k0ki-dev.de/normafreeland\r\n\r\n\r\nhttps://git.thweb.net/harleywheaton\r\n\r\n\r\nhttps://gitea.cybs.io/ixkmodesto0899/blackcoin.co6431/wiki/Skycrown-Casino-Australia-Sign-Up-%243000-%2B-200-FS-Bonus\r\n\r\n\r\nhttps://mockway.cpolar.top/alenalomax242\r\n\r\n\r\nhttps://www.oddmate.com/@adolphdeshotel\r\n\r\n\r\nhttps://gogs.pinadshub.com/cecilegertz166\r\n\r\n\r\nhttps://git.dadunode.com/karolyng99783\r\n\r\n\r\nhttps://pokesoul.com/@danielen39920\r\n\r\n\r\nhttps://quickdate.arenascript.de/@younglienhop7\r\n\r\n\r\nhttps://k0ki-dev.com/molliestukes32\r\n\r\n\r\nhttps://gitea.pnkx.top:8/desireebair01\r\n\r\n\r\nhttps://k8cutv01.it.ntnu.no/louiechristmas/3917959/wiki/Expert+Review+2025\r\n\r\n\r\nhttps://gitea.noname-studios.es/nelsongillen9\r\n\r\n\r\nhttps://git.bpcspace.com/damarismosely4\r\n\r\n\r\nhttps://git.droenska.com/traceynibbi346\r\n\r\n\r\nhttps://gogs.artapp.cn/giachristensen

https://git.bloade.com/amberlabonte91\r\n\r\n\r\nhttps://slowdating.ca/@lakeishaxwa158\r\n\r\n\r\nhttps://music.michaelmknight.com/angelowrixon10\r\n\r\n\r\nhttps://scrape.weidautzel.de/carmellaneuman\r\n\r\n\r\nhttps://gitea.my-intrudair.com/jakemarconi27/1440222/wiki/Grand-opening-of-long-awaited-Hard-Rock-Casino-Tejon\r\n\r\n\r\nhttps://vcs.int.feuerwehr-ziemetshausen.de/damarisavey91\r\n\r\n\r\nhttps://git.lokalix.de/jonathona16314/2108blackcoin.co/wiki/Login\r\n\r\n\r\nhttps://leafreward.com/read-blog/7060_new-online-casinos-in-australia-top-10-picks-for-2025.html\r\n\r\n\r\nhttps://pleroma.cnuc.nu/evamackennal15/eva2023/wiki/Las-Vegas-Slot-Machines\r\n\r\n\r\nhttps://git.auwiesen2.de/nicholasoneill\r\n\r\n\r\nhttps://git.outsidecontext.solutions/bessiemcgarry3/4798blackcoin.co/wiki/Claim-Up-To-%242000-%2B-100-Free-Spins\r\n\r\n\r\nhttps://lekoxnfx.com:4000/timmenard5925\r\n\r\n\r\nhttps://gitea.freeyoursystem.de/tsiaimee907824\r\n\r\n\r\nhttps://gitea.tpss.top/marylyn34s5682\r\n\r\n\r\nhttps://heylloow.com/@jeseniaztu8159\r\n\r\n\r\nhttps://www.jr-it-services.de:3000/agnesnichols9\r\n\r\n\r\nhttps://git.arx-obscura.de/gregallie16834\r\n\r\n\r\nhttps://www.ilife24.com/rogerfortin143\r\n\r\n\r\nhttps://gitea.xtometa.com/elanemattison0/2347250/wiki/Gambler-wins-%241-18M-jackpot-at-Tachi-Palace-Casino\r\n\r\n\r\nhttps://k0ki-dev.com/alfonzo473499\r\n\r\n\r\nhttps://gitea.svc.obaa.cloud/adela57f654869

https://grafana.jasonstolle.com/adanreddy05054/adan2009/wiki/Casino-Royale-2006-Streaming-Where-to-Watch-Online\r\n\r\n\r\nhttps://git.bpcspace.com/alanna52415098\r\n\r\n\r\nhttps://wondermap.org/read-blog/8112_las-vegas-hotel-room-deals.html\r\n\r\n\r\nhttps://speeddating.co.il/@wileyoflaherty\r\n\r\n\r\nhttps://git.barsisr.fr/carmellalardne\r\n\r\n\r\nhttps://www.chembans.com/@melvinvarnum73\r\n\r\n\r\nhttps://giteap.grobest.com:3000/armandr6501893\r\n\r\n\r\nhttps://git.hundseth.com/dellaedwards27\r\n\r\n\r\nhttps://gitea.tpss.top/buckbanning87\r\n\r\n\r\nhttps://gogs.kakaranet.com/alexisdas8465/8777782/wiki/App\r\n\r\n\r\nhttps://www.jr-it-services.de:3000/josettebruce1\r\n\r\n\r\nhttps://gitea.blubeacon.com/rubyecordeaux9\r\n\r\n\r\nhttps://isabelzarate.com/tahliaedkins91\r\n\r\n\r\nhttps://git.getmind.cn/harriettalbarr\r\n\r\n\r\nhttps://nrisoulmate.com/@alizaboynton02\r\n\r\n\r\nhttps://www.chaorendata.shop/reynatorreggia\r\n\r\n\r\nhttps://koseongnam.com/corteztietkens\r\n\r\n\r\nhttps://gitlab.ngser.com/lucasmagnus841\r\n\r\n\r\nhttps://git.sudo-fhir.au/alejandrahersh\r\n\r\n\r\nhttps://www.soundofrecovery.org/andreagoulet45\r\n\r\n\r\nhttps://gt.clarifylife.net/adrienee28858

http://60.204.158.188:3000/jennyhauser284/jenny2024/wiki/Best-Online-Rocket-Play-Casino-Experience\r\n\r\n\r\nhttps://git.daneric.dev/josephhedges72\r\n\r\n\r\nhttps://www.e-vinil.ro/chuproeschel59\r\n\r\n\r\nhttps://git.bremauer.cc/antoniomortime/blackcoin5883/wiki/Comprehensive-Review-and-Features\r\n\r\n\r\nhttps://unillel-paraversum.de/jeremiahscherf/jeremiah2011/wiki/Best+Online+Pokies+and+Free+Spins\r\n\r\n\r\nhttps://sithcom.de/patsysharkey4\r\n\r\n\r\nhttp://bluecell.synology.me:3000/clarices080727\r\n\r\n\r\nhttps://gitea.micro-stack.org/susannahfix518/6066022/wiki/Get-a-300%25-bonus-up-to-CAD-3%2C000-plus-100-free-spins-on-your-first-two-deposits%21\r\n\r\n\r\nhttps://git.simbarbet.com/aidanpagan493/aidan2024/wiki/Get-Welcome-Bonus%3A-A%245000-%2B-500FS\r\n\r\n\r\nhttps://git.ellinger.eu/aleidastradbro\r\n\r\n\r\nhttps://gogs.qindingtech.com/qxemadge19510/blackcoin.co4027/wiki/King+Billy+Casino+Bonuses+for+Every+Royal+Player\r\n\r\n\r\nhttps://gogs.bardels.me/bzbkerstin7934/2670blackcoin.co/wiki/Best+Online+Casinos+for+Real+Money+in+the+US+Top+Casino+Sites\r\n\r\n\r\nhttps://qrew.social/read-blog/10732_crown-towers-sydney-review-hotel-delivers-the-wow-factor-city-has-been-missing.html\r\n\r\n\r\nhttps://git.louislabs.com/aliciacanterbu\r\n\r\n\r\nhttps://www.arabianmatrimony.com/@leehilliard22\r\n\r\n\r\nhttps://gitea.freeyoursystem.de/blanchemarriot\r\n\r\n\r\nhttps://lensez.info/ronny562529738\r\n\r\n\r\nhttps://liebiwelle.com/@alanavela02052\r\n\r\n\r\nhttps://git.hsy.com/celiaalaniz290\r\n\r\n\r\nhttps://git.healthathome.com.np/brethussain601\r\n\r\n\r\nhttps://gogs.optch.top/hopeschneider

https://gogs.optch.top/gerikopsen335\r\n\r\n\r\nhttps://gogs.koljastrohm-games.com/rudysadler0816\r\n\r\n\r\nhttps://gogs.gaokeyun.cn/kristensherman\r\n\r\n\r\nhttps://net.smartedge.com.ng/read-blog/9890_richard-casino-review-no-deposit-bonus-30-free-spins.html\r\n\r\n\r\nhttps://www.latflex.net/@josefamollison?page=about\r\n\r\n\r\nhttps://qrew.social/read-blog/10754_official-website-in-australia-2025.html\r\n\r\n\r\nhttps://gitea.springforest.top/aimeestingley\r\n\r\n\r\nhttp://server.ayaojies.com.cn:3000/terrellgardene/blackcoin2010/wiki/Skycrown%253A+A+Top+Online+Casino+for+Aussie+Players+Reviewed\r\n\r\n\r\nhttps://www.oddmate.com/@amado994528757\r\n\r\n\r\nhttps://www.simpra.org:3000/brenton1555322\r\n\r\n\r\nhttps://gitea.freeyoursystem.de/blanchemarriot\r\n\r\n\r\nhttps://natgeophoto.com/pearlenepratte\r\n\r\n\r\nhttp://softwarescience.top:3000/markmarte75842/mark1985/wiki/Top+10+Online+Casinos+for+Real+Money+in+Australia+November+2025\r\n\r\n\r\nhttps://gogs.pinadshub.com/nannieccq11911\r\n\r\n\r\nhttps://www.e-vinil.ro/chuproeschel59\r\n\r\n\r\nhttps://theindievibes.com/joycelynyeo31\r\n\r\n\r\nhttps://www.fastmarry.com/@adelehain53977\r\n\r\n\r\nhttps://git.kitti.ac.th/ralfdon0856863/ralf2011/wiki/Top+5+sweepstakes+casinos+in+November+2025%3A+Get+a+free+no-deposit+bonus+%26+more.-\r\n\r\n\r\nhttps://projects.om-office.de/luannmichaelis\r\n\r\n\r\nhttps://pilowtalks.com/@albertinagarre\r\n\r\n\r\nhttp://gitea.liaozhuangkeji.com/francescovando

https://www.soundofrecovery.org/blanchevela55\r\n\r\n\r\nhttps://git.lakaweb.com/felipegerrard6/felipe1995/wiki/Top-Online-Casino-Games-to-Gamble-for-Real-Money-in-2025\r\n\r\n\r\nhttps://hgngit.ipdz.me/georgegann604\r\n\r\n\r\nhttps://kamtk.ru:4000/louisacharles3\r\n\r\n\r\nhttps://www.simpra.org:3000/elmahurtado688\r\n\r\n\r\nhttps://git.bremauer.cc/antoniomortime/blackcoin5883/wiki/Comprehensive-Review-and-Features\r\n\r\n\r\nhttps://whatchats.com/read-blog/8647_what-is-going-on-with-the-crown-casino-in-sydney.html\r\n\r\n\r\nhttps://git.kitti.ac.th/tanishajge039\r\n\r\n\r\nhttps://gogs.storlead.com/andreas65e7373\r\n\r\n\r\nhttps://gitea.ysme.top/brandipflaum6\r\n\r\n\r\nhttps://git.anacsoft.com/sherriecounsel\r\n\r\n\r\nhttps://git.qingbs.com/millieschubert\r\n\r\n\r\nhttps://gitnto.innovationcampus.ru/kathleneharbis\r\n\r\n\r\nhttps://gitea.micro-stack.org/bernardopolson/5788165/wiki/Foxwoods-Casino%2C-CT-Weather-Forecast\r\n\r\n\r\nhttps://lekoxnfx.com:4000/sammymarston04/blackcoin9287/wiki/Claim+a+Bonus+Offer+of+up+to+400+EUR\r\n\r\n\r\nhttps://sound.descreated.com/cornelllahey05\r\n\r\n\r\nhttps://jenkins.txuki.duckdns.org/alphonsohinson\r\n\r\n\r\nhttps://home.zhupei.me:3000/anastasiacarl\r\n\r\n\r\nhttps://playxtream.com/@ebonygillis390?page=about\r\n\r\n\r\nhttps://gitea.ysme.top/danniefitzpatr/blackcoin.co3743/wiki/Official-Site-Login\r\n\r\n\r\nhttps://git.memosnag.com/charoletterome

https://gitea.ysme.top/alisiaboldt656/blackcoin.co4157/wiki/Richard-Casino-Bis-zu-5000-Bonus-Registrierung-Login\r\n\r\n\r\nhttps://scrape.weidautzel.de/aidenangas4419\r\n\r\n\r\nhttps://git.rbsx.de/juniorslaughte/junior1980/wiki/Best-Mobile-Casinos-2025-Play-Casino-Games-On-Your-Phone\r\n\r\n\r\nhttps://lekoxnfx.com:4000/christif11530\r\n\r\n\r\nhttps://git.bremauer.cc/sadyecalloway/2846blackcoin/wiki/Ricky-Casino-Australia-2025-%E2%AD%90-Massive-AU$7%2C500-Bonus-+-550-FS\r\n\r\n\r\nhttps://maintain.basejy.com/alfiem9756785\r\n\r\n\r\nhttps://surily.in/bufordrobe4698\r\n\r\n\r\nhttps://lekoxnfx.com:4000/dalenebei24614/blackcoin1986/wiki/SkyCrown+Casino+Australia%253A+Fair+Review+About+Games+and+Bonuses\r\n\r\n\r\nhttps://hiphopmusique.com/angelascott191\r\n\r\n\r\nhttp://gitea.liaozhuangkeji.com/francescovando\r\n\r\n\r\nhttps://gitea.dusays.com/alonzogoheen7\r\n\r\n\r\nhttps://git.aopcloud.com/dsuemilio1018/blackcoin.co8670/wiki/King-Billy-Casino-Australia-%E1%90%88-King-Billy-Online-Login\r\n\r\n\r\nhttps://gogs.pinadshub.com/etta48m7605515\r\n\r\n\r\nhttps://gogs.bardels.me/mableconey064/mable1993/wiki/Luxury+Gaming%252C+Hotel%252C+Dining+%2526+Entertainment\r\n\r\n\r\nhttps://hiphopmusique.com/caryguidry1499\r\n\r\n\r\nhttps://gitea.coderpath.com/alishajelks56/9452331/wiki/Play-19%2C430+-Free-Slot-Games-98-5%25-RTP-No-Download\r\n\r\n\r\nhttps://www.globaltubedaddy.com/@langiffen55128?page=about\r\n\r\n\r\nhttps://quickdatescript.com/@olivehogue374\r\n\r\n\r\nhttps://mockway.cpolar.top/jonasybarra044\r\n\r\n\r\nhttps://seferpanim.com/read-blog/41452_best-online-casinos-in-australia-top-real-money-casinos-in-2025.html\r\n\r\n\r\nhttps://git.fandiyuan.com/simonpatrick57/blackcoin2016/wiki/Skycrown-Online-Casino%3A-Exploring-the-Exhilarating-World

https://www.simpra.org:3000/guillermomcphe\r\n\r\n\r\nhttps://gogs.dev.dazesoft.cn/wadearmitage32\r\n\r\n\r\nhttps://git.kraft-werk.si//aracelycraig9/blackcoin2908/-/issues/2\r\n\r\n\r\nhttps://ralphouensanga.com/read-blog/54973_australians-best-online-casino.html\r\n\r\n\r\nhttps://csmsound.exagopartners.com/sabineperrier4\r\n\r\n\r\nhttps://omayaa.com/read-blog/6401_fair-go-casino-free-chip-codes-july-2025-bonus-update.html\r\n\r\n\r\nhttps://quickdatescript.com/@keithtrout457\r\n\r\n\r\nhttps://healedonly.com/@ashleealfaro01\r\n\r\n\r\nhttps://git.clarue.net/bradychinn183\r\n\r\n\r\nhttps://gitstud.cunbm.utcluj.ro/herman69048690\r\n\r\n\r\nhttps://sexwifed.com/@darrellherrman?page=about\r\n\r\n\r\nhttps://qrew.social/read-blog/10732_crown-towers-sydney-review-hotel-delivers-the-wow-factor-city-has-been-missing.html\r\n\r\n\r\nhttps://git.camus.cat/desiree97g434\r\n\r\n\r\nhttps://git.slegeir.com/jon5619623413\r\n\r\n\r\nhttps://gogs.optch.top/agneswarkentin\r\n\r\n\r\nhttps://www.simpra.org:3000/rosemarycolley\r\n\r\n\r\nhttps://lesla.com/@txefranziska94\r\n\r\n\r\nhttps://gitea.nongnghiepso.com/naomijackman25/naomi2019/wiki/The-Best-Online-Casino-Choices-in-Australia\r\n\r\n\r\nhttps://git.ecq.jp/adalombardo024/blackcoin2023/wiki/Casino-railway-station-Wikipedia\r\n\r\n\r\nhttps://surily.in/christacamaren\r\n\r\n\r\nhttps://git.ellinger.eu/sheenaalberts/sheena2009/wiki/Royal-Rewards-for-Aussies

https://git.fur93.cn:8002/traciu24523963\r\n\r\n\r\nhttps://www.kornerspot.com/@arnoldmoorman6\r\n\r\n\r\nhttps://soundrecords.zamworg.com/stantongrenier\r\n\r\n\r\nhttps://schsocial.com/read-blog/22495_top-online-casino-amp-sports-betting-in-australia.html\r\n\r\n\r\nhttps://git.daoyoucloud.com/andyohman0721/3441496/wiki/Online-Kaszin%C3%B3-Magyarorsz%C3%A1gon\r\n\r\n\r\nhttps://gt.clarifylife.net/belenh92629523\r\n\r\n\r\nhttps://git.simbarbet.com/aidanpagan493/aidan2024/wiki/Play\r\n\r\n\r\nhttps://git.jamieede.com/calebmarmion6\r\n\r\n\r\nhttps://selfloveaffirmations.net/@calebmacon6119\r\n\r\n\r\nhttps://palchat.top/read-blog/9489_play-slots-table-games-amp-live-casino-online.html\r\n\r\n\r\nhttps://git.lokalix.de/andrewdeniehy/5360696/wiki/Gonzo-Casino-No-Deposit-Bonus-Code-2025\r\n\r\n\r\nhttps://matchmingle.fun/@rigobertoespie\r\n\r\n\r\nhttps://vila.go.ro/leandrondy0109\r\n\r\n\r\nhttps://git.hanckh.top/gertienorton0\r\n\r\n\r\nhttps://sound.gatzone.com/terrellpayton\r\n\r\n\r\nhttps://gitea.gimmin.com/chance5613630\r\n\r\n\r\nhttps://img.lodis.se/adolphbinns87\r\n\r\n\r\nhttps://ralphouensanga.com/read-blog/54984_about-us-minnesota-casino-hotel-and-event-center-in-mahnomen-minnesota.html\r\n\r\n\r\nhttps://repos.ubtob.net/margaritaoconn\r\n\r\n\r\nhttps://matchmingle.fun/@rochellehoyle\r\n\r\n\r\nhttps://git.fhlz.top/devinnull95910/blackcoin1985/wiki/Star-Entertainment-Clings-to-Life-After-Unloading-Brisbane-Casino

https://git.vhdltool.com/aguedaamaya50\r\n\r\n\r\nhttps://gitea.mpc-web.jp/alishagoodin0/blackcoin2002/wiki/Bagley-Home-Minnesota-Casino%2C-Hotel-and-Event-Center-in-Mahnomen%2C-Minnesota\r\n\r\n\r\nhttps://git.getmind.cn/alfredtunstall\r\n\r\n\r\nhttps://socialmedia.smartup.com.bo/read-blog/64370_casino-royale-film-fandom.html\r\n\r\n\r\nhttps://dreamplacesai.de/makaylakitchen\r\n\r\n\r\nhttps://nrimatchmaking.com/@paigeeaster175\r\n\r\n\r\nhttps://maru.bnkode.com/@dustyserena07\r\n\r\n\r\nhttps://www.simpra.org:3000/rosemarycolley\r\n\r\n\r\nhttps://www.muslimlove.com/@angelinawimber\r\n\r\n\r\nhttps://gogs.bardels.me/bzbkerstin7934/2670blackcoin.co/wiki/Best+Online+Casinos+for+Real+Money+in+the+US+Top+Casino+Sites\r\n\r\n\r\nhttps://pleroma.cnuc.nu/marlysh6034160/5155751/wiki/Play-Slots%2C-Table-Games-%26-Live-Casino-Online\r\n\r\n\r\nhttps://git.louislabs.com/antoniahurley3\r\n\r\n\r\nhttps://palkwall.com/read-blog/82072_casino-mate-australia-trusted-online-casino-for-real-money-play.html\r\n\r\n\r\nhttps://jovita.com/ieshagaunt027\r\n\r\n\r\nhttp://51234.fun:3000/rodneymasel68\r\n\r\n\r\nhttps://luvwing.com/@adrienefrey683\r\n\r\n\r\nhttps://healedonly.com/@bernadettegowi\r\n\r\n\r\nhttps://syq.im:2025/shirleenponce/blackcoin.co1546/wiki/SkyCrown-Casino-Review-%26-Rating-2025\r\n\r\n\r\nhttps://www.lab.justusdeitert.de/adolfograve817\r\n\r\n\r\nhttps://syq.im:2025/mayra89667410/7402blackcoin.co/wiki/Login%2C-Welcome-Bonus-Up-To-%241000\r\n\r\n\r\nhttps://nas.zearon.com:2001/alexhewlett063/alex2020/wiki/Play-on-the-official-site

https://app.globalteachershub.com/read-blog/54341_leon-casino-france-bonus-15-000-200-tours-gratuits.html\r\n\r\n\r\nhttps://theindievibes.com/arron581584335\r\n\r\n\r\nhttps://suksesvol.org/read-blog/78963_casino-nsw.html\r\n\r\n\r\nhttps://git.ism-dev.net/abbiedalgarno8\r\n\r\n\r\nhttps://rc.intaps.com/jefferymeister/blackcoin.co2019/wiki/Skycrown-Casino-Review-By-Experts-2025-Is-Casino-Legit-%26-Safe%3F\r\n\r\n\r\nhttps://repos.ubtob.net/celia07f276162/celia1998/wiki/Sign+In+to+Your+Account+Safely\r\n\r\n\r\nhttps://gogs.pinadshub.com/maritzakaler5/3559blackcoin/wiki/Enchanting+Ventures+in+the+Realm+of+WS+Casino\r\n\r\n\r\nhttps://bdgit.educoder.net/emersonlear811/5942155/wiki/Online-Casino-Games-for-Real-Money-24-7-at-DraftKings-Casino\r\n\r\n\r\nhttps://git.agri-sys.com/dariosauer0908\r\n\r\n\r\nhttps://git.barneo-tech.com/alfiefountain5\r\n\r\n\r\nhttps://git.lodis.se/antonio969655/blackcoin1981/wiki/The-Star-Brisbane\r\n\r\n\r\nhttps://gogs.gaokeyun.cn/dustynolan9958\r\n\r\n\r\nhttps://koljastrohm-games.com:3000/arturopardey6\r\n\r\n\r\nhttps://palchat.top/read-blog/9490_ozwin-casino-sign-up-and-get-welcome-bonus-up-to-4000-100-fs.html\r\n\r\n\r\nhttps://lambrg.com/read-blog/17857_online-pokies-mobile-play-amp-fast-au-withdrawals.html\r\n\r\n\r\nhttps://git.limework.net/jamesfreeleagu\r\n\r\n\r\nhttps://theindievibes.com/arron581584335\r\n\r\n\r\nhttps://www.aservicehost.ru/alanawaldron92/blackcoin.co1992/wiki/Expert-Review-2025\r\n\r\n\r\nhttps://moonifie.com/read-blog/87134_get-up-to-ca-7500-bonus.html\r\n\r\n\r\nhttps://git.unicom.studio/hassiebussey32\r\n\r\n\r\nhttps://git.bpcspace.com/nqqkrista39930

https://urlb.link/fideliafawkner\r\n\r\n\r\nhttps://dadjobs.es/employer/rocketplay-no-deposit-bonus-codes-australia-august-2024/\r\n\r\n\r\nhttps://chat.thekphub.com/elanabelbin62\r\n\r\n\r\nhttps://webmasterteam.net/debora51f0\r\n\r\n\r\nhttps://jobsleed.com/companies/rocketplay-casino-bonuses-no-deposit-bonus-codes-november-2025/\r\n\r\n\r\nhttps://hmljobs.com/employer/2367/king-billy-casino-review-2025-hot-or-not\r\n\r\n\r\nhttps://www.bookmyaccountant.co/profile/numbersfavenc\r\n\r\n\r\nhttps://365.expresso.blog/question/catastrophic-risk-why-star-shares-have-lost-25-in-4-days/\r\n\r\n\r\nhttps://urlb.link/lgxkristofer4\r\n\r\n\r\nhttps://profalink.com/ineslaughl\r\n\r\n\r\nhttps://kaiftravels.com/employer/rocketplay-no-deposit-bonus-codes-and-free-spins-updated/\r\n\r\n\r\nhttp://rudavision.com/bbs/board.php?bo_table=free&wr_id=1579581\r\n\r\n\r\nhttps://digital-skill-jobs.web-grafix.in/employer/sgr-asx-star-entertainments-mystery-macau-backer-hikes-stake-for-second-time-in-a-week/\r\n\r\n\r\nhttps://ttl01.com/bbs/board.php?bo_table=free&wr_id=355121\r\n\r\n\r\nhttp://www.lingoli.io/bbs/board.php?bo_table=free&wr_id=57\r\n\r\n\r\nhttps://webtily.com/jocelynp008273\r\n\r\n\r\nhttps://flamingo.onl/horaciosch\r\n\r\n\r\nhttps://barkindia.in/employer/townsville-casino-menu/\r\n\r\n\r\nhttps://mylinku.com/phildenman\r\n\r\n\r\nhttps://www.cbkps.com/bbs/board.php?bo_table=free&wr_id=323563\r\n\r\n\r\nhttp://successintransition.com/companies/new-south-wales-gambling-guide-online-casinos-in-nsw/

https://kota.lk/adamuramats719\r\n\r\n\r\nhttps://epsart.kr/bbs/board.php?bo_table=free&wr_id=1193\r\n\r\n\r\nhttps://liixor.site/alannahower178\r\n\r\n\r\nhttps://jobsrific.com/employer/sydney-casino-accommodations-for-unforgettable-stays/\r\n\r\n\r\nhttps://firstmaid.sg/companies/rocketplay-casino-no-deposit-bonuses-50-free-spins-book-of-cats/\r\n\r\n\r\nhttps://hwekimchi.gabia.io/bbs/board.php?bo_table=free&tbl=&wr_id=1292947\r\n\r\n\r\nhttp://copya.co.kr/bbs/board.php?bo_table=free&wr_id=505353\r\n\r\n\r\nhttps://manpoweradvisors.com/employer/7bit-casino-officially-play-top-slots-games/\r\n\r\n\r\nhttps://99link.me/GsVNl\r\n\r\n\r\nhttps://jobteck.com.sg/companies/online-bonuses-free-spins-on-registration/\r\n\r\n\r\nhttps://jobm8.com/employer/crown-sydney-luxury-gaming-destination/\r\n\r\n\r\nhttps://www.ayurjobs.net/employer/online-bonuses-free-spins-on-registration/\r\n\r\n\r\nhttps://jobsinodisha.org/companies/fast-payout-online-casinos-australia-neospin-picked-as-the/\r\n\r\n\r\nhttps://jobinaus.com.au/companies/no-deposit-bonuses-at-rocketplay-online-casino-conditions-for-getting-and-limits-on-the-use/\r\n\r\n\r\nhttps://links.senc.in/billyrestrepo\r\n\r\n\r\nhttp://jobteck.com/companies/rocket-play-casino-no-deposit-bonus-codes-2025-free-chips/\r\n\r\n\r\nhttps://qr.nub-1.com/aidanstone560\r\n\r\n\r\nhttps://wschang.synology.me/g5/bbs/board.php?bo_table=free&wr_id=3825\r\n\r\n\r\nhttps://kaiftravels.com/employer/rocketplay-no-deposit-bonus-codes-and-free-spins-updated/\r\n\r\n\r\nhttps://africajobland.com/employer/claim-10-free-bonus-to-all-new-players/\r\n\r\n\r\nhttps://freevcards.com/erickaradcliff

https://www.jobseeker.my/employer/trusted-online-casino-reviews-2025/\r\n\r\n\r\nhttps://cz-link.click/broderickboggs\r\n\r\n\r\nhttps://aimetath.com/torriwilfred14\r\n\r\n\r\nhttps://oclick.top/vcont\r\n\r\n\r\nhttps://skillsvault.co.za/profile/chaucoury6296\r\n\r\n\r\nhttps://europejobs.cloud/companies/instant-payouts-and-hot-daily-bonuses/\r\n\r\n\r\nhttps://divyangrojgar.com/employer/best-crypto-casino-online/\r\n\r\n\r\nhttps://aimetath.com/torriwilfred14\r\n\r\n\r\nhttps://myjobsquote.com/employer/ozwin-casino-login-unlock-epic-bonuses-and-slots-today/\r\n\r\n\r\nhttps://khongdaidong.click/caridadgandy4\r\n\r\n\r\nhttps://legaljobsireland.com/employer/king-billy-casino-review-2025/\r\n\r\n\r\nhttps://gspcareer.com/employer/gold-coast-hotel-and-casino-las-vegas-nevada-us/\r\n\r\n\r\nhttp://mail.morningstar24.com/bbs/board.php?bo_table=free&wr_id=320474\r\n\r\n\r\nhttps://teba.timbaktuu.com/employer/%ef%b8%8f-bonuses-2500-and-250-free-spins/\r\n\r\n\r\nhttps://articleship.in/companies/king-billy-casino-australia-2025/\r\n\r\n\r\nhttps://chefstronomy.co.za/employer/star-entertainment-keeps-sydney-casino-open-but-fined-again/\r\n\r\n\r\nhttps://urlcliq.com/stewart49r1519\r\n\r\n\r\nhttps://jobflux.eu/employer/295728/cairns-casino-australian-gaming-entertainment-culture-guide\r\n\r\n\r\nhttps://hirekaroo.com/companies/townsville-casino-the-ville/\r\n\r\n\r\nhttp://mjf.xn--hy1b90it0ofnk.com/bbs/board.php?bo_table=free&wr_id=180408\r\n\r\n\r\nhttps://career.agricodeexpo.org/employer/16594/top-100-real-money-online-casinos-2025

https://linksbr.com.br/mattierudd\r\n\r\n\r\nhttps://ueb.li/claudequinto85\r\n\r\n\r\nhttps://jobrails.co.uk/employer/7bitcasino-crypto-gambling-site/\r\n\r\n\r\nhttps://abtl.ink/melbawesto\r\n\r\n\r\nhttps://linksshortcut.com/ninabeale53732\r\n\r\n\r\nhttp://www.leeonespa.com/bbs/board.php?bo_table=free&wr_id=91\r\n\r\n\r\nhttp://cloud4.co.kr/bbs/board.php?bo_table=data&wr_id=651487\r\n\r\n\r\nhttps://volunteeri.com/companies/best-online-casino-bonus-australia-top-casino-promos-2025/\r\n\r\n\r\nhttps://jobsindatacenter.com/employer/sgr-star-entertainment-has-a-stalker-rather-than-a-saviour/\r\n\r\n\r\nhttps://fskdigital.com/dannhusk128231\r\n\r\n\r\nhttp://www.129koreaems.com/bbs/board.php?bo_table=free&wr_id=8\r\n\r\n\r\nhttps://aurelus.link/travisgranvill\r\n\r\n\r\nhttps://distaq.online/employer/the-star-sydney/\r\n\r\n\r\nhttp://global.gwangju.ac.kr/bbs/board.php?bo_table=g0101&wr_id=1295983\r\n\r\n\r\nhttps://minilink.nl/kathie4790830\r\n\r\n\r\nhttps://www.startup-door.com/employer/joe-fortune-casino-aussie-focused-fast-crypto-payouts-400-games/\r\n\r\n\r\nhttps://shortlinks.com.tr/dora69h280175\r\n\r\n\r\nhttps://dubicly.com/employer/best-real-money-online-casinos-for-the-usa-2025/\r\n\r\n\r\nhttps://pettahbazaar.lk/employer/national-casino-review-bonuses-promotions-games/\r\n\r\n\r\nhttps://zenfilm.solutions/veolashuman21\r\n\r\n\r\nhttp://www.vcard.orizensoft.com/ginacarver2063

malaysia central gaming\r\n\r\n\r\nhttps://slimly.site/charolettefrit slimly.site\r\n\r\n\r\nhttp://jobs.recruithub.africa/profile/stephanymaupin http://jobs.recruithub.africa/\r\n\r\n\r\nhttps://updatel.ink/pedrospaull87 https://updatel.ink/\r\n\r\n\r\nhttps://pridestaffing.us/companies/stay/ pridestaffing.us\r\n\r\n\r\nhttps://grupokandidat.com/compa%C3%B1ias/premium-slots-live-dealers-elite-rewards/ grupokandidat.com\r\n\r\n\r\nhttps://gamjobs.com/employers/21bit-casino-bonuses-codes-2-november-2025/ gamjobs.com\r\n\r\n\r\nhttps://marine-courses.com/employer/star-casino-shares-holding-on-for-dear-life-heres-the-latest/ https://marine-courses.com/employer/star-casino-shares-holding-on-for-dear-life-heres-the-latest\r\n\r\n\r\nhttps://www.punjabbazar.com/user/profile/brodiebyrne/item_type,active/per_page,16 punjabbazar.com\r\n\r\n\r\nhttps://mapnova.com.co/employer/access-your-vip-gaming-experience/ mapnova.com.co\r\n\r\n\r\nhttps://gagubada.co.kr/bbs/board.php?bo_table=free&wr_id=20 https://gagubada.co.kr\r\n\r\n\r\nhttps://www.ip-exhibitions.net/employer/best-online-casinos-australia-paying-real-money-2025/ www.ip-exhibitions.net\r\n\r\n\r\nhttps://www.jw-test.com/bbs/board.php?bo_table=free&wr_id=341 https://www.jw-test.com\r\n\r\n\r\nhttps://minilink.nl/ceciliaj717965 minilink.nl\r\n\r\n\r\nhttps://xsurl.in/jeromebyn3767 https://xsurl.in/jeromebyn3767\r\n\r\n\r\nhttps://workfind.in/profile/maikkimber8611 workfind.in\r\n\r\n\r\nhttps://onlinejob.lk/employer/21bit-decode-your-path-to-victory/ https://onlinejob.lk\r\n\r\n\r\nhttp://excelrenforcement.com/companies/pullman-reef-hotel-casino-luxury-cairns-hotel-accor/ http://excelrenforcement.com/\r\n\r\n\r\nhttp://www.busungbio.co.kr/bbs/board.php?bo_table=free&wr_id=58786 http://www.busungbio.co.kr/bbs/board.php?bo_table=free&wr_id=58786

https://linksminify.com/dalec481413664\r\n\r\n\r\nhttps://jobs.ethio-academy.com/employer/online-casinos-for-real-money-2025-best-paying-online-casinos-usa/\r\n\r\n\r\nhttps://ashkert.am/%D5%A1%D5%B7%D5%AF%D5%A5%D6%80%D5%BF%D5%AB-%D5%B0%D5%A1%D5%B4%D5%A1%D6%80/top-online-casino-for-aus-usa-players/\r\n\r\n\r\nhttps://heres.link/jewelcohn27515\r\n\r\n\r\nhttps://chefstronomy.co.za/employer/rocketplay-casino-no-deposit-bonus-codes-november-2025/\r\n\r\n\r\nhttps://myjobsquote.com/employer/ozwin-casino-login-unlock-epic-bonuses-and-slots-today/\r\n\r\n\r\nhttp://makeshare.org/bbs/board.php?bo_table=news&wr_id=90\r\n\r\n\r\nhttps://ashkert.am/%D5%A1%D5%B7%D5%AF%D5%A5%D6%80%D5%BF%D5%AB-%D5%B0%D5%A1%D5%B4%D5%A1%D6%80/top-online-casino-for-aus-usa-players/\r\n\r\n\r\nhttps://tictaccollection.life/sadietuck66045\r\n\r\n\r\nhttp://jimiantech.com/g5/bbs/board.php?bo_table=w0dace2gxo&wr_id=973624\r\n\r\n\r\nhttps://jobteck.com.sg/companies/king-billy-casino-reviews-read-customer-service-reviews-of-www-kingbillycasino-com/\r\n\r\n\r\nhttps://bio.shipfry.com/elizaleroy\r\n\r\n\r\nhttps://duct.co.kr/ru/bbs/board.php?bo_table=free&wr_id=57539\r\n\r\n\r\nhttps://www.cdlcruzdasalmas.com.br/portal_de_empregos/companies/national-casino-canada-your-unforgettable-gambling-experience/\r\n\r\n\r\nhttps://some.center/bbs/board.php?bo_table=free&wr_id=793283\r\n\r\n\r\nhttps://grupokandidat.com/compa%C3%B1ias/star-casino-share-price-online-casino-2020/\r\n\r\n\r\nhttps://ibio.app/vdbmiles27\r\n\r\n\r\nhttp://play123.co.kr/bbs/board.php?bo_table=online&wr_id=230662\r\n\r\n\r\nhttps://bk-careers.com/companies/national-casino-login-and-registration-nationalcasino-mobile-app/\r\n\r\n\r\nhttps://profalink.com/rigobertos\r\n\r\n\r\nhttps://qr-th.com/michellkilving

basic blackjack strategy\r\n\r\n\r\nhttps://jobsharmony.com/companies/21bit-org-promotions-the-best-casino-bonuses-online/ https://jobsharmony.com/companies/21bit-org-promotions-the-best-casino-bonuses-online\r\n\r\n\r\nhttps://built.molvp.net/rosalieldj https://built.molvp.net/rosalieldj\r\n\r\n\r\nhttps://guvenilirkisaltma.cfd/richiebradshaw guvenilirkisaltma.cfd\r\n\r\n\r\nhttps://forwardingjobs.com/companies/cashman-casino-exceptional-online-gaming-experience/ forwardingjobs.com\r\n\r\n\r\nhttps://ezonnerecruit.com/employer/king-billy-casino-australia-play-for-real-money-in-2025/ https://ezonnerecruit.com/\r\n\r\n\r\nhttp://gyeongshin.co.kr/kscn/bbs/board.php?bo_table=free&wr_id=912570 gyeongshin.co.kr\r\n\r\n\r\nhttp://norwegia.praca-ok.pl/author/charlottehu/ norwegia.praca-ok.pl\r\n\r\n\r\nhttps://bezraboten.com/employer/fast-secure-access/ https://bezraboten.com\r\n\r\n\r\nhttps://bk-careers.com/companies/cashman-casino-free-coins-november-2025/ bk-careers.com\r\n\r\n\r\nhttps://agenceglobalpro.com/employer/7500/2025-australia-legal-online-casinos-aussie-online-casinos agenceglobalpro.com\r\n\r\n\r\nhttps://www.startup-door.com/employer/best-online-casinos-for-real-money-in-the-usa-2025/ www.startup-door.com\r\n\r\n\r\nhttps://dancemua.com/bbs/board.php?bo_table=free&wr_id=438479 https://dancemua.com\r\n\r\n\r\nhttps://appbitly.com/willianbetanco https://appbitly.com/\r\n\r\n\r\nhttps://grupokandidat.com/compa%C3%B1ias/online-casino-real-money-guide-top-apps-and-legal-states-in-2025/ grupokandidat.com\r\n\r\n\r\nhttps://urlxh.com/ofeliabordelon urlxh.com\r\n\r\n\r\nhttps://minilink.nl/jenniferfether minilink.nl\r\n\r\n\r\nhttp://mail.morningstar24.com/bbs/board.php?bo_table=free&wr_id=320081 mail.morningstar24.com\r\n\r\n\r\nhttps://hirenhigher.co.nz/companies/a-high-rollers-guide-to-sydneys-biggest-casinos/ hirenhigher.co.nz

http://nursedaum.com/bbs/board.php?bo_table=free&wr_id=11\r\n\r\n\r\nhttp://ttceducation.co.kr/bbs/board.php?bo_table=free&wr_id=3029524\r\n\r\n\r\nhttps://urlcliq.com/teodorofranco0\r\n\r\n\r\nhttp://play123.co.kr/bbs/board.php?bo_table=online&wr_id=230731\r\n\r\n\r\nhttp://hi-d.co.kr/bbs/board.php?bo_table=free&wr_id=427125\r\n\r\n\r\nhttp://bnclogis.net/board/bbs/board.php?bo_table=free&wr_id=771142\r\n\r\n\r\nhttps://quicklancer.bylancer.com/profile/untcora603529\r\n\r\n\r\nhttps://www.makemyjobs.in/companies/the-star,-sydney-star-city-casino/\r\n\r\n\r\nhttps://alfacareers.com/employer/the-ville-resort-casino-wikipedia/\r\n\r\n\r\nhttps://gizemarket.com/companies/ozwin-casino-login-unlock-epic-bonuses-and-slots-today/\r\n\r\n\r\nhttps://kor.fromkorea.kr/bbs/board.php?bo_table=free&wr_id=2990\r\n\r\n\r\nhttps://oapk.online/raymundoamv004\r\n\r\n\r\nhttps://clarktour.co.kr/g5/bbs/board.php?bo_table=free&wr_id=43\r\n\r\n\r\nhttps://links.senc.in/natishaa51923\r\n\r\n\r\nhttp://ww.yeosunet.com/bbs/board.php?bo_table=free&wr_id=159560\r\n\r\n\r\nhttps://vetanhanguera.shop/ritaa90130\r\n\r\n\r\nhttp://shop.ororo.co.kr/bbs/board.php?bo_table=free&wr_id=4505662\r\n\r\n\r\nhttps://skillmais.com/companies/what-is-the-star-casino-share-price-really-worth/\r\n\r\n\r\nhttps://seeurl.site/lisetteb011043\r\n\r\n\r\nhttps://myjobsquote.com/employer/national-casino-review-bonuses-promotions-games/\r\n\r\n\r\nhttps://chat.thekphub.com/liammate81691

https://www.smilecarexport.com/bbs/board.php?bo_table=free&wr_id=53\r\n\r\n\r\nhttps://www.aytokariyer.com.tr/employer/bonus-400-up-to-4000-for-australia/\r\n\r\n\r\nhttps://pandahouse.lolipop.jp:443/g5/bbs/board.php?bo_table=aaa&wr_id=3025409\r\n\r\n\r\nhttps://jobs.khtp.com.my/employer/9162/king-billy-casino-australia-login-get-bonus-au2500-250-fs/\r\n\r\n\r\nhttps://getshort.in/danielejefferi\r\n\r\n\r\nhttp://thdeco.com/bbs/board.php?bo_table=free&wr_id=331783\r\n\r\n\r\nhttp://aanline.com/eng/board/bbs/board.php?bo_table=free&wr_id=173007\r\n\r\n\r\nhttps://link-me.vip/gretaweddle68\r\n\r\n\r\nhttp://skmagicrent.com/bbs/board.php?bo_table=free&wr_id=7\r\n\r\n\r\nhttps://alfacareers.com/employer/the-ville-resort-casino-wikipedia/\r\n\r\n\r\nhttps://clarktour.co.kr/g5/bbs/board.php?bo_table=free&wr_id=43\r\n\r\n\r\nhttps://audiorooms-radio.de/lloydbourgeois\r\n\r\n\r\nhttps://www.3scomputers.com/partheniaashbu\r\n\r\n\r\nhttps://chaakri.com/employer/secure-access-to-your-gaming-account/\r\n\r\n\r\nhttps://ttl01.com/bbs/board.php?bo_table=free&wr_id=355132\r\n\r\n\r\nhttps://bezraboten.com/employer/start-with-a2500-250-fs-bonus/\r\n\r\n\r\nhttp://copya.co.kr/bbs/board.php?bo_table=free&wr_id=505644\r\n\r\n\r\nhttps://chahed-recrutement.com/employer/14000-games-and-crypto-withdrawals/\r\n\r\n\r\nhttps://short.vird.co/simafeetham50\r\n\r\n\r\nhttps://getshort.in/charlireece723\r\n\r\n\r\nhttps://beshortlisted.com/employer/7bit-casino-usa-slots-live-dealer-games-and-fast-payouts-online/

https://volunteeri.com/companies/1500-aud-bonus-on-registration/\r\n\r\n\r\nhttps://portal.shcba.org/employer/australias-most-thrilling-online-casino/\r\n\r\n\r\nhttps://ethiofarmers.com/online-casinos-australia-best-aussie-casino-sites-of-2025/\r\n\r\n\r\nhttps://www.fanz.ing/jdnadeline445\r\n\r\n\r\nhttps://7box.de/loUcf\r\n\r\n\r\nhttps://fskdigital.com/uyzlouise40514\r\n\r\n\r\nhttps://fskdigital.com/uyzlouise40514\r\n\r\n\r\nhttps://n28.it/shawnbreeze570\r\n\r\n\r\nhttps://niftyhire.com/companies/top-5-new-australian-online-casinos-for-2025/\r\n\r\n\r\nhttps://beauty4g.shop/jefferyblanche\r\n\r\n\r\nhttps://profalink.com/rigobertos\r\n\r\n\r\nhttps://www.vurke.com/employer/gold-coast-casino-everything-to-know-before-a-visit/\r\n\r\n\r\nhttps://www.startup-door.com/employer/10-best-real-money-online-casinos-in-australia-for-2025-february-update/\r\n\r\n\r\nhttps://ghibta.org/employer/best-real-money-australian-online-casino-sites-for-2025/\r\n\r\n\r\nhttps://infolokerbali.com/employer/gold-coast-hotel-and-casino/\r\n\r\n\r\nhttps://myjobsquote.com/employer/national-casino-review-bonuses-promotions-games/\r\n\r\n\r\nhttps://bilzainvisa.com/employer/the-best-online-casino-choices-in-australia/\r\n\r\n\r\nhttps://trlink.me/marciasisc\r\n\r\n\r\nhttps://sosjob.ca/employer/star-entertainment-tumbles-on-fresh-warning-asx-rises-trump-meme-coin-price-swings-as-it-happened/\r\n\r\n\r\nhttps://fdjobvacancies.com/employer/login-welcome-pack-c2500-250-fs/\r\n\r\n\r\nhttps://ashkert.am/%D5%A1%D5%B7%D5%AF%D5%A5%D6%80%D5%BF%D5%AB-%D5%B0%D5%A1%D5%B4%D5%A1%D6%80/top-online-casino-for-aus-usa-players/

https://gunnersmart.com - Where Owning a gun is a smart life Choice

Teacup Shih Tzu Welpen Adoption in Europa\r\n\r\nhttps://shihtzulieblinge.com

Premier USA registered home Sphynx & Devon Rex breeders\r\n -Exotic Beauty. Purebred Purrfection\r\n— Adopt exotic blue-eyed Sphynx kittens in the USA\r\nhttps://rexotickittens.com/product-category/sphynx/\r\nfind Devon Rex beauties near me.

Adoptieren Sie gesunde Englische und Französische Bulldoggenwelpen europaweit \r\nmit https://champion-bulldoggen.com/shop/\r\n. Wir bieten flexible Adoptionspläne und kostenlosen Versand in viele Städte. \r\nEntdecken Sie verfügbare Welpen unter https://champion-bulldoggen.com/blog/\r\n und https://champion-bulldoggen.com/\r\n.\r\n\r\nMehr Informationen zu unseren Adoptionsplänen finden Sie hier:\r\nhttps://champion-bulldoggen.com/adoptionsplane/\r\n\r\nVergleich aller Optionen:

Leave a Comment